Industry Background and Market Demand

Reactive power is an intrinsic component of alternating current (AC) power systems. It arises from the phase difference between voltage and current when inductive or capacitive elements are present in the load. While reactive power does not contribute to useful work, it represents energy that oscillates between source and load and impacts apparent power delivered in the system. If unmanaged, excessive reactive power leads to poor power factor, elevated losses, and increased thermal stress on conductors and transformers.

Utility providers often impose penalties for low power factor, or they may require corrective measures to ensure grid stability. This regulatory and operational context has fueled demand for power quality solutions that dynamically manage reactive power. Reactive Power Compensation Controllers are central to such solutions, directing Capacitor banks, Reactors, or power electronic units to balance reactive energy, improve power factor, and maintain system stability.

Core Concept and Key Technology

A Controller For Reactive Power Compensation is a digital control device that monitors electrical parameters and orchestrates compensation actions to maintain a stable power factor or reactive power level. These controllers continuously assess system voltage, current, and power factor, deciding when to engage or disengage reactive power sources such as capacitor steps or Thyristor‑switched reactors. Advanced controllers integrate multiple measurements and compensation strategies to adapt to varying load conditions and network characteristics.

At the core of a modern Reactive Power Controller is a microprocessor or digital signal processor (DSP) that executes control algorithms, samples real‑time electrical quantities, and sends command signals to switching devices. These devices can include electromechanical contactors or semiconductors such as thyristors or triacs, depending on response speed and system requirements. Controllers often support both automatic and manual modes, enabling floor engineers to operate or override system behavior when needed.

Critical to controller effectiveness is the ability to evaluate and respond to real‑time reactive power demands. This is achieved through advanced sampling of voltage and current waveforms, computation of reactive power or power factor, and conditional logic that triggers compensation steps based on defined thresholds. Controllers may also include protective logic to avoid overcompensation, frequent switching, or resonance issues.

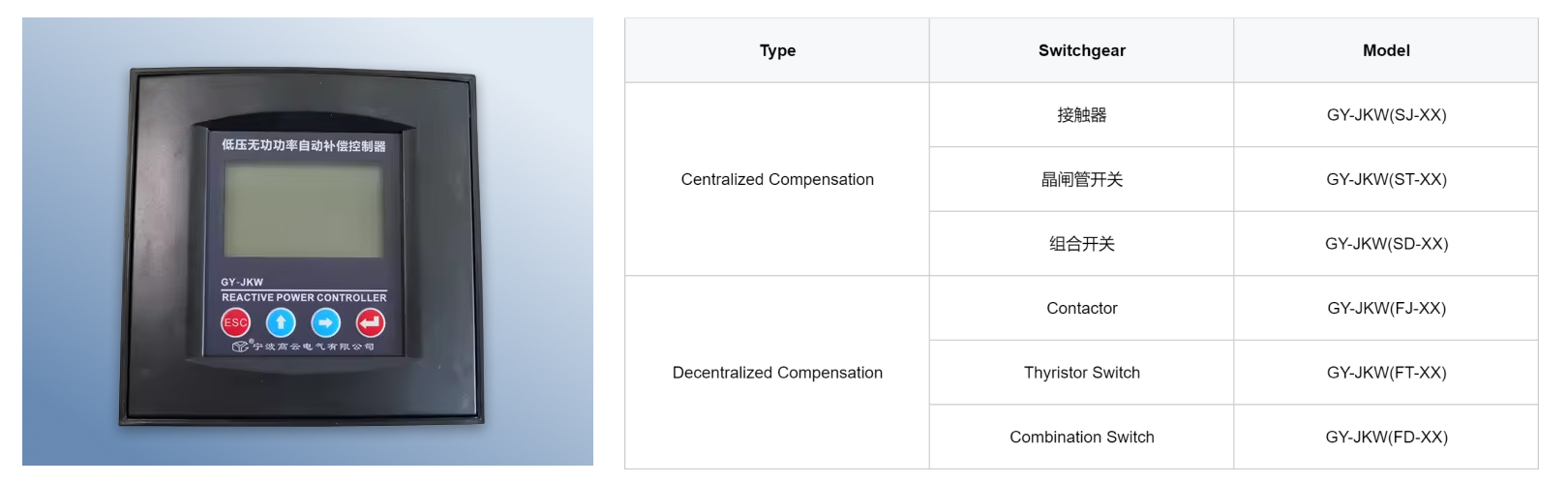

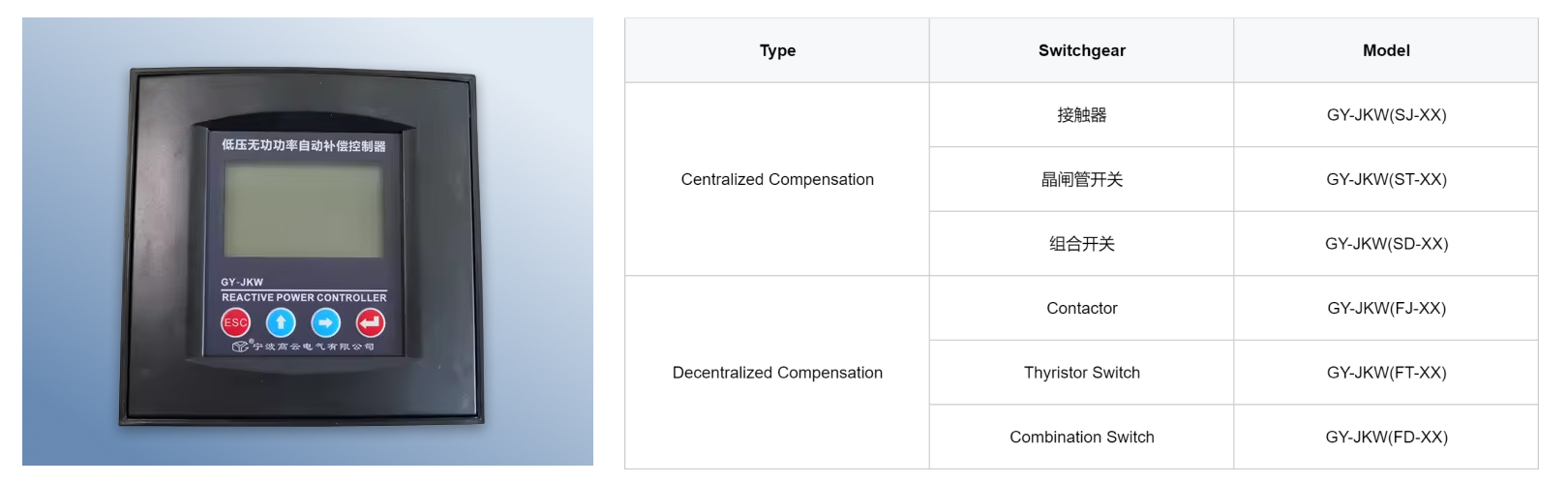

Product Structure, Performance, Materials, and Manufacturing

A typical reactive power compensation controller includes several key modules:

1. Measurement Unit

The measurement subsystem incorporates voltage and current inputs, often via current transformers (CTs) and potential transformers (PTs). It continuously samples electrical parameters and feeds digitized signals to the control core. The fidelity of this unit strongly influences compensation accuracy and response times.

2. Control and Processing Module

This is the controller’s computing heart. High‑performance microprocessors or DSPs execute compensation algorithms, manage logic decisions, and communicate with external interfaces. This module must be robust to electrical noise, temperature fluctuations, and voltage transients typical of industrial environments.

3. Output Switching Interface

Depending on system design, controllers may drive contactors, thyristor switches, or Combination Switch circuits to connect or disconnect capacitor banks and reactors. The choice of switching technology affects both the lifetime and the switching speed of the compensation system.

4. User Interface and Communication

Modern controllers often feature displays, indicator LEDs, or status outputs that inform on current compensation status, power factor levels, and faults. Some models include communication interfaces such as RS‑485 or Modbus for integration with supervisory control and data acquisition (SCADA) systems.

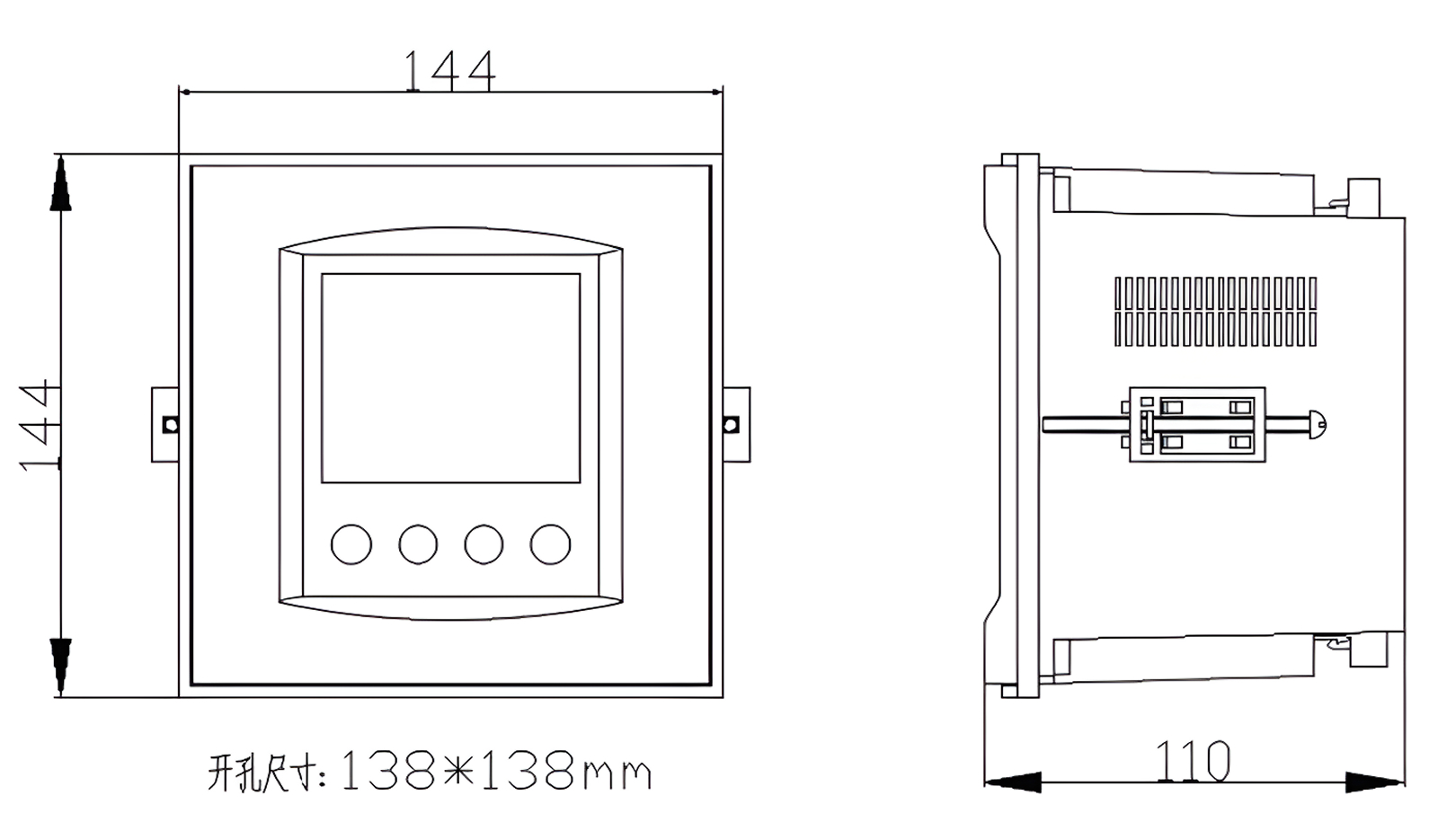

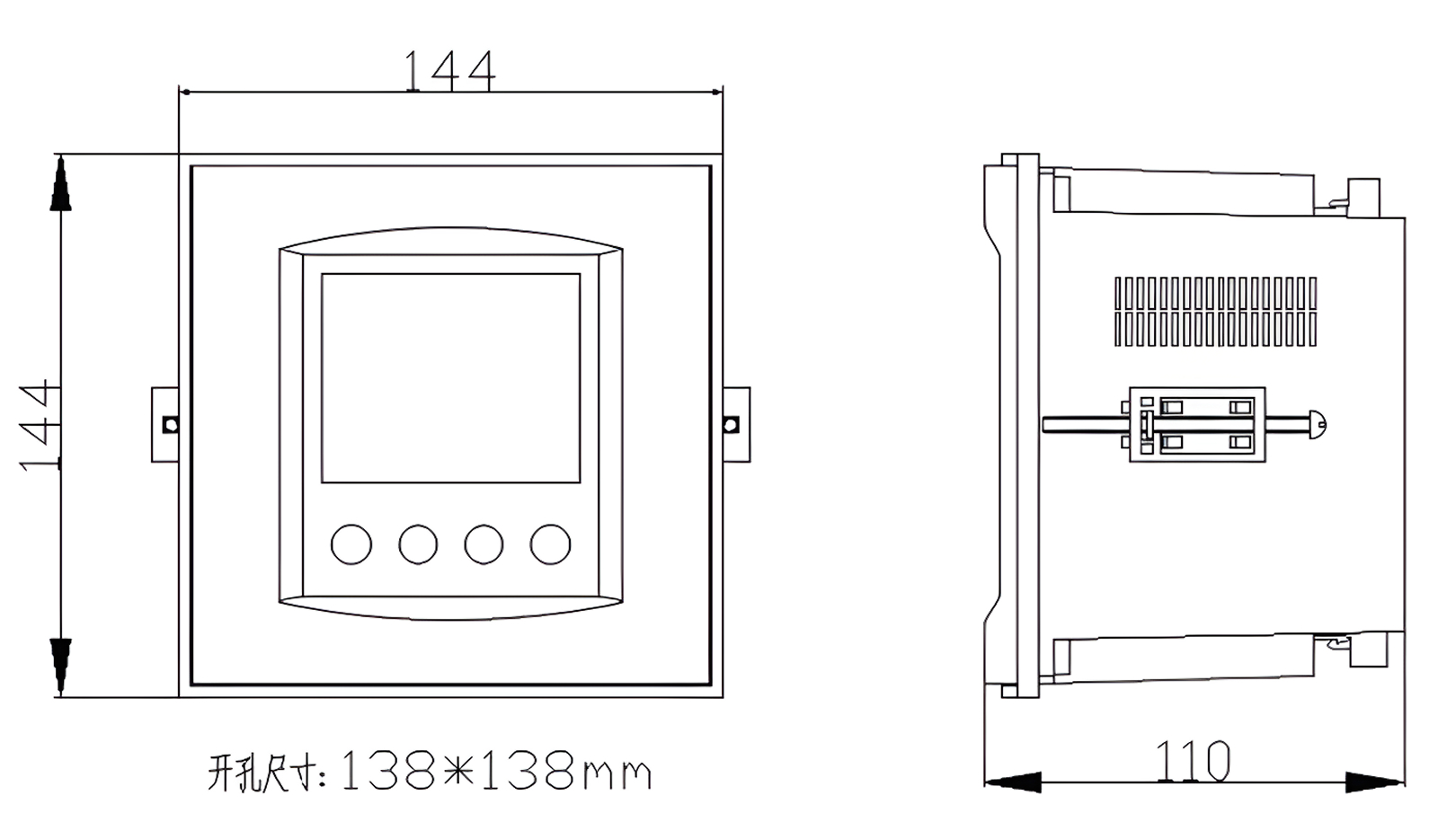

5. Housing and Materials

Controllers are usually housed in industrial enclosures rated for indoor use, with materials selected for electrical insulation, thermal resilience, and mechanical protection. Metal or high‑grade polymer enclosures are common in harsh industrial settings.

The manufacturing process emphasizes precision in analog front‑end circuitry, digital calibration, and robust firmware that ensures consistent operation across varied load conditions and network disturbances.

Factors Influencing Quality and Performance

Several elements determine the performance of a reactive power controller:

Measurement Precision

The accuracy of voltage and current sampling directly impacts the quality of compensation. Poor measurement can lead to incorrect switching decisions, reduced power factor improvement, and system instability.

Algorithm Responsiveness

Controllers with advanced algorithms adapt more effectively to fast load changes and nonlinear load profiles. Algorithms must balance responsiveness with stability to avoid rapid switching that shortens contactor life or induces electrical noise.

Protection and Interlocks

Automatic protection against overvoltage, undervoltage, and excessive switching events can prolong both controller and capacitor bank life. Built‑in protection reduces the risk of capacitor resonance and electrical stress.

Environmental Robustness

Controller electronics must withstand industrial conditions such as temperature extremes, humidity, vibration, and electrical interference. Enclosures, component selection, and thermal design all influence reliability.

Supply Chain and Supplier Selection Standards

Selecting a supplier for reactive power controllers is a strategic decision that influences long‑term system reliability and operational cost. Key procurement criteria include:

Standards Compliance: Products should adhere to recognized standards for electrical measurement accuracy and safety, such as IEC or IEEE power quality and safety norms. Suppliers with documented compliance and third‑party certification enhance trust.

Technical Support and Documentation: Comprehensive manuals, wiring diagrams, parameter guides, and responsive support services ensure correct system commissioning and maintenance.

Component Traceability: Suppliers that disclose key component origins, quality testing protocols, and batch traceability provide higher assurance of consistency.

Scalability and Modularity: For distribution networks with expanding load requirements, controllers that support expansion or integration with larger power management systems are preferable.

After‑Sales Service: Given the central role of controllers in reactive power management, warranty terms, spare parts availability, and regional service presence are crucial.

Common Challenges and Industry Pain Points

Even with advanced controllers, reactive power compensation systems face practical challenges:

Harmonic Interference

Nonlinear loads generate harmonics that affect measurement accuracy and switch performance. Controllers must either filter measured signals or incorporate harmonic‑aware algorithms to avoid misinterpretation of reactive demand.

Switching Wear and Optimum Step Selection

Frequent switching can wear mechanical components and generate electrical transients. Controllers must be tuned to minimize unnecessary switching while maintaining desired power factor targets.

Load Variability

Rapid load fluctuations in manufacturing processes require controllers that can adapt without causing instability in compensation. Poorly tuned systems may overcompensate or lag behind actual demand.

Integration Complexity

Controllers must coexist with other power quality equipment, including passive filters, reactors, and active filtering solutions. Inadequate integration may lead to resonance, unstable compensation, or equipment stress.

Application Scenarios and Use Cases

Industrial Distribution Systems

In manufacturing plants, induction motors, welding equipment, and power conversion devices typically draw significant reactive current. Controllers regulate capacitor banks to maintain a high power factor, reduce line losses, and avoid utility penalties.

Commercial Buildings

Large HVAC systems, elevators, and lighting loads contribute to reactive demand. Controllers help optimize building energy profiles and reduce peak apparent power draw.

Renewable Energy Systems

Systems integrating wind turbines or solar inverters often introduce variable reactive requirements due to fluctuating generation. Controllers ensure the distribution system remains balanced and compliant with grid voltage regulations.

Utility Substations

Controllers can be deployed as part of centralized compensation schemes, automatically managing bank switching in response to grid conditions, thereby enhancing stability and reducing system losses.

Current Trends and Future Development

Intelligent Compensation Algorithms

Future controllers incorporate machine‑learning‑assisted algorithms that predict reactive demand patterns based on historical load profiles and grid conditions, enabling proactive compensation strategies.

Integration with Smart Grids

As smart grid technologies evolve, controllers increasingly communicate with grid management platforms to contribute to holistic energy optimization, voltage regulation, and ancillary services.

Enhanced Monitoring and Remote Management

Integration with IoT and cloud platforms enables remote monitoring, performance analytics, and firmware updates, improving uptime and reducing maintenance costs.

Hybrid Compensation Architectures

Reactive power controllers are being designed to operate in hybrid systems that leverage both passive elements and power electronic compensation for optimized performance across a variety of load types and harmonic environments.

Frequently Asked Questions (FAQ)

Q: Why is reactive power compensation necessary?

Reactive power compensation improves power factor, stabilizes voltage levels, reduces losses in conductors and transformers, and minimizes charges associated with low power factor in industrial tariffs.

Q: How does a reactive power controller differ from a simple contactor bank?

A controller continuously monitors real‑time electrical parameters and makes intelligent switching decisions based on measured needs, whereas a simple contactor bank lacks measurement and decision logic.

Q: What influences the switching frequency of a controller?

Switching frequency is primarily influenced by load variability, compensation algorithm settings, and threshold parameters for reactive power correction.

English

English

Español

Español

Portugues

Portugues

Pусский

Pусский

Français

Français

Deutsch

Deutsch

日本語

日本語

한국어

한국어

العربية

العربية

Italiano

Italiano

Nederlands

Nederlands

Svenska

Svenska

Polski

Polski

Türk dili

Türk dili

हिन्दी

हिन्दी

Indonesia

Indonesia

Melayu

Melayu

dansk

dansk

Magyar

Magyar

қазақ

қазақ

বাংলা

বাংলা

עִברִית

עִברִית

čeština

čeština

українська

українська

Filipino

Filipino

Suomalainen

Suomalainen

اردو

اردو

հայերեն

հայերեն

български

български

Hrvatski

Hrvatski

galego

galego

नेपाल

नेपाल

euskara

euskara

Shqipëria

Shqipëria

Malagasy

Malagasy

Башҡорт

Башҡорт

Türkmenler

Türkmenler

Ilocano

Ilocano

Нохчийн

Нохчийн

WhatsApp

WhatsApp тэлефон

тэлефон